History more than 58 years

The Company History Deuschle Spindel-Service GmbH

Paying attention to details is the difference between mediocrity and excellence. Our goal: Excellence.

History

| Year | Event | |

|---|---|---|

| 2024 | CO2 milestone: Photovoltaic PV system 135kW was installed for 80% own energy supply | |

| 2023 | New machine: CMM of ZEISS Contura was installed | |

| 2022 | Kellenberger CNC machine KelVaria was installed | |

| 2022 | Pro-Spindle China Spindle Repair Workshop - Deuschle is JV partner | |

| 2021 | Membership in the BVMW "Federal Association of Small and Medium-Sized Enterprises", the largest business association in Germany. | |

| 2020 | Deuschle puts the 6th grinding machine and the 4th lathe machine as well as a 2nd laser welding system into operation | |

| 2019 | Stepping up into precision parts manufacturing with CNC machine tools. MAZAK INTEGREX, 4 axix milling, laser engraving etc. | |

| 2018 | Deuschle Bisingen has 37 employees / Deuschle Korea 8 employees / more than 30.000 repaired Spindles | |

| 2017 | Environment Certification ISO 14001:2015 achieved | |

| 2016 | 50 Years DEUSCHLE | |

| 2015 | Metrology: Deuschle buys a MAHR measuring machine | |

| 2014 | Deuschle Bisingen got 32 employees and achieved about 26.000 repaired spindle units | |

| 2014 | Deuschle Korea employes 8 workers | |

| 2013 | ISO 9001:2008 Certification in Germany and Korea is achieved | |

| 2012 | Cooperation with CAPELLINI SRL, Italy begins | |

| 2012 | Foundation of the Deuschle Korea Ltd. in Seoul (South Korea) | |

| 2010 | Certification DIN EN ISO 9001:2008 in Korea and Bisingen achieved | |

| 2008 | 3D measuring machine with highest accuracy was installed NIKON METRIS | |

| 2003 | Leadership transferred to the 2. generation with the sons Samuel Deuschle and Jonathan Deuschle | |

| 2002 | Agent with FISCHER and PRECISE ends | |

| 1999 | Relocation to Bisingen with 2000m2 area | |

| 1994 | Deuschle develops and manufactures the first own spindle | |

| 1989 | Relocation to own company building in Gottlieb-Daimler-Str. 1 | |

| 1988 | 1. Exhibition at the AMB in Stuttgart | |

| 1985 | Relocation to the industrial estate Denkendorf with around 300m2 | |

| 1980 | Relocation of the factory to into the summerhouse with 40m2 | |

| 1978 | 1. Exhibition at the FAMETA in Stuttgart | |

| 1974 | DEUSCHLE becomes agent of FISCHER Spindles, Switzerland and PRECISE, Germany | |

| 1973 | 1. Workshop in residence of the company founder Karl Deuschle | |

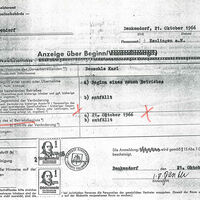

| 1966 | Legal registration of Business |

How everything started

For decades, Deuschle Spindel-Service GmbH has specialized in the repair and production of spindle units. This began in 1966 with our founder, Karl Deuschle offering his expertise in HSC (High-speed cutting) technology. As a consultant, he laid down the foundation for offering excellent services for spindles. The same approach has informed the company‘s current market strategy, which is completely customer-oriented and constantly optimized.

Due to increasing demand, along with increasingly individual development of mechanical and automotive engineering, Deuschle has been challenged to redefine concepts of service. These innovations range from the classic change of new bearings, the regrinding and balancing of components, as well as retrofits up to the development of new spindle systems with integrated Industry 4.0 capabilities. Our extensive know-how of over 50 years has been honored by many loyal customers.

The Deuschle team consists of over 50 qualified employees in Germany with a subsidiary in South Korea and China. We operate in several industries including metalwork, energy, electronics, medical technology, as well as in the wood and plastics industries. Wherever we are mentioned, Deuschle is named as a potential supplier and an excellent partner.

Exceptional customer service enables the company to be on the pulse of the times. In doing so, Deuschle focuses on customers who demand timely and customized project specification. For customers with defined machinery repair, we offer contracts to service and maintain their spindles. Deuschle also conducts modifications on existing spindles, with new spindle developments being carried out in close collaboration with the customer. We utilize the “PTC Creo Parametric” CAD system for this purpose.

As a system supplier, Deuschle not only services and delivers the spindle itself, we also supply all peripheral devices that are required for the smooth operation of a spindle system. These include frequency converters, cooling units, tool holders, finely filtered lubricants and other accessories; exchange spindles are available as well.