Balancing conform to DIN ISO norm

Balancing

Balancing all rotary parts of the spindle system is essential. This affects every type of spindle equally. A possible imbalance can arise not only from components within the spindle, but also from the use of the tools / tool holder. It is therefore important to balance the spindle system from the inside as best as possible, but to allow tools and tool holders to follow the balancing immediately.

When manufacturing new spindles and repairing a spindle, all rotating parts are first statically pre-balanced and dynamically re-balanced in the test field. We work with SCHENCK balancing devices, stationary and mobile. Made in Germany.

What kind of parts can be balanced according to DIN ISO 1940-1 ?

- all spindle parts itself

- HSK, ISO, SK, BT tool holders

- Spindle shafts partially assembled or complete

- rotors, rotor shafts

- couplings

- fan blades, fans

- grinding arbors

generally up to 200 kg of rotating mass and 500 kg unit weight

Why this emphasis on balancing?

The balance quality of a spindle system results from:

Balancing quality of the spindle / drive

+ Balance quality of the tool holder

+ Balance quality tools

= Total balance quality

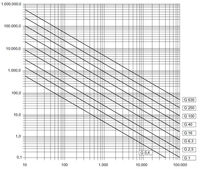

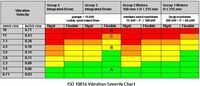

The balancing quality G 2.5 at nominal speed is therefore a standard in our work. In many cases this is guaranteed by spindle technology, but not up to the tool / tool holder. It is therefore important to balance all rotary parts according to this standard in order to avoid premature, avoidable failures.

Balancing types

According to ISO, a rigid rotor can be balanced in 2 levels (perpendicular to the rotor axis) by adding or reducing masses in this two balancing levels. A rigid rotor is called as such if the balancing quality is independent of the operating speed (for the entire range from zero up to the permitted maximum speed). The condition just described can be assumed in most cases in milling and grinding spindles. For rigid rotors are two types of imbalance can be distinguished.

Whether you are dealing with precision spindles, rotors for the aeronautical or aerospace industries, high-speed tools or drive components: Our balancing service will assure a high level of quality for your high-performance products.